Mastering Resistance Spot Welding: Calibration for Consistency

Resistance spot welding, a crucial process in automotive manufacturing for joining metal body panels…….

Welcome to an in-depth exploration of a transformative process that has revolutionized industrial manufacturing: Resistance Spot Welding (RSW). This article aims to guide you through the intricacies of RSW, from its fundamental principles to its global impact and future prospects. By delving into various aspects, we will uncover how this welding technique shapes industries, drives economic growth, and addresses technological challenges. Get ready to discover a process that is far more than just metal joining—it’s a catalyst for innovation across sectors.

Definition: Resistance Spot Welding is a precision metal-joining technique where localized heat is generated by resisting electric current flow through a small area of contact between two components. This process fuses the metals, creating a strong and permanent bond.

Core Components:

Historical Context:

RSW traces its origins back to the late 19th century when early forms of resistance welding emerged. However, significant advancements were made during World War II for aircraft manufacturing, leading to its widespread adoption in various industries. Over time, technological improvements have refined RSW, making it highly versatile and efficient.

Significance:

RSW has left an indelible mark on global manufacturing, with its influence extending across continents. Here’s a glimpse into its international impact:

| Region | Impact and Trends |

|---|---|

| North America | Dominant in the automotive industry, RSW is being adopted for light-weighting and advanced steel grades. |

| Europe | Leading edge in robotized RSW systems, with a focus on sustainability and reduced emissions. |

| Asia Pacific | Rapid growth in consumer electronics and home appliances sectors drives RSW demand. |

| Middle East & Africa | Increasing use in oil and gas infrastructure projects, leveraging RSW for corrosion-resistant joints. |

| South America | Emerging markets adopting RSW for automotive and aerospace components due to cost-effectiveness. |

Key Trends:

The economic landscape of RSW is a complex web of market dynamics and investment patterns.

Market Dynamics:

Investment Patterns:

Economic Impact:

RSW’s evolution is marked by groundbreaking technological innovations that continue to shape the industry:

Future Potential:

The legal framework surrounding RSW is designed to ensure safety, environmental protection, and fair trade practices.

Key Policies and Regulations:

Influence on Development:

Despite its numerous advantages, RSW faces certain challenges and criticisms that require addressing for sustained growth.

Main Challenges:

Criticisms:

Proposed Solutions:

Let’s explore a few case studies that highlight the effective implementation of RSW in diverse industries.

Case Study 1: Automotive Industry – Toyota Motor Corporation

Toyota utilized RSW extensively in its production lines, achieving significant benefits. By implementing automated RSW systems, they reduced assembly time and improved consistency in joining high-strength steel components. This led to lighter vehicles with enhanced safety features, aligning with Toyota’s eco-friendly and innovative reputation.

Case Study 2: Electronics Assembly – Apple Inc.

Apple’s iPhone manufacturing heavily relies on RSW for precise component bonding. Advanced robotic systems ensure consistent welds, creating durable and aesthetically pleasing devices. This precision assembly contributes to the high-quality standards associated with Apple products.

Case Study 3: Aerospace Manufacturing – Boeing Company

Boeing employs RSW for joining advanced aluminum alloys in aircraft structures. This technique enables complex component fabrication while maintaining structural integrity. By minimizing welding defects, Boeing ensures the safety and performance of its aircraft, solidifying its position as a leader in aviation.

The future of RSW is filled with promising growth areas and emerging trends that will shape the industry’s trajectory.

Potential Growth Areas:

Emerging Trends:

Strategic Considerations:

Resistance Spot Welding has undeniably left an indelible mark on modern manufacturing, offering unparalleled precision and efficiency. Its global impact is evident across industries, from automotive to aerospace and electronics. As technology advances and demands evolve, RSW continues to adapt, addressing challenges while embracing new opportunities.

The future prospects for RSW are bright, with potential breakthroughs in material joining, digitalization, and sustainability. By navigating the policies, overcoming criticisms, and leveraging emerging trends, this powerful welding technique will remain a cornerstone of industrial advancement. As we conclude, it’s clear that RSW is not just a process but a catalyst for innovation, driving industries forward into a new era of manufacturing excellence.

Q: What are the primary advantages of Resistance Spot Welding?

A: RSW offers precision control, high production rates, reduced labor costs, and the ability to join various metals. It ensures strong, permanent bonds, making it ideal for mass manufacturing.

Q: Can RSW be used for joining plastics?

A: While RSW is primarily used for metal joining, some advanced applications have explored its potential for certain types of plastics. However, material compatibility remains a challenge, and further research is needed.

Q: How does RSW contribute to sustainability in manufacturing?

A: RSW can be made more sustainable by adopting energy-efficient equipment, using eco-friendly electrode materials, and implementing waste reduction strategies. These practices minimize environmental impact while maintaining high-quality welds.

Q: Are there any safety risks associated with RSW?

A: Like any welding process, RSW has inherent safety risks, including heat exposure, noise, and vibration. Proper personal protective equipment (PPE) and machine design can mitigate these risks. Regular safety training is essential for operators.

Q: Can RSW be automated for high-volume production?

A: Absolutely! Automation is a key trend in RSW, with industrial robots capable of precise, consistent welding. This streamlines production, improves quality, and reduces labor costs.

Resistance spot welding, a crucial process in automotive manufacturing for joining metal body panels…….

Resistance spot welding is a precise, efficient automotive technique using electrical current to mel…….

Squeeze-type resistance spot welding is a preferred method among Original Equipment Manufacturers (O…….

Resistance spot welding is a versatile, efficient technique used in automotive repairs for precise w…….

Resistance spot welding (RSW) is an advanced automotive repair technique prioritizing precision and…….

Resistance spot welding (RSW) revolutionizes auto body repair with swift, precise bonding of metal s…….

Resistance spot welding is a cutting-edge automotive repair technique that provides precise, localiz…….

Resistance Spot Welding (RSW) is an advanced technique used in the automotive industry for efficient…….

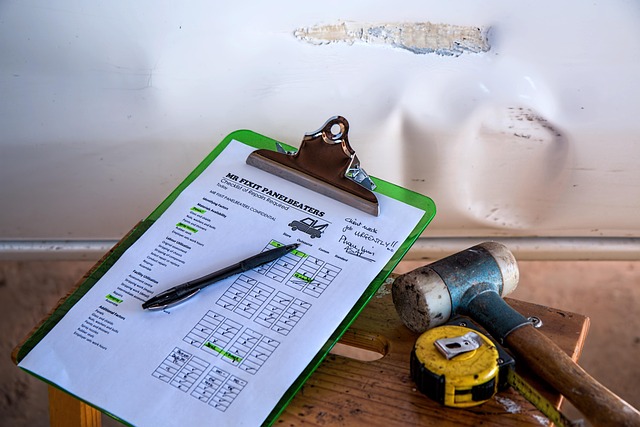

Resistance spot welding is a precise metal joining technique used in automotive paintless dent repai…….

Resistance spot welding (RSW) is a powerful and precise joining technique that has revolutionized au…….