Resistance spot welding relies on heat and pressure to create strong, consistent fuses. Precise control of these factors is vital for high-quality welds across diverse industries, from automotive repair to metal fabrication. Excessive or insufficient heat, or improper pressure, leads to poor weld quality, including distortion and weak bonds. Auto collision centers utilize advanced techniques and equipment to fine-tune parameters, ensuring structural integrity and industry standard compliance during operations like auto glass replacement and frame straightening.

“Unveiling the power dynamics behind resistance spot welding, this article delves into the intricate dance of heat and pressure. Discover how these fundamental forces shape the quality and strength of welds, offering a profound understanding of this precision manufacturing process.

From the instant melting of metals to the creation of robust bonds, we explore ‘Understanding Heat’s Role’ and ‘The Impact of Pressure’. Furthermore, learn about optimizing these parameters for efficient, consistent spot welding.”

- Understanding Heat's Role in Resistance Spot Welding

- The Impact of Pressure on Welding Quality and Strength

- Optimizing Heat and Pressure for Efficient Spot Welding

Understanding Heat's Role in Resistance Spot Welding

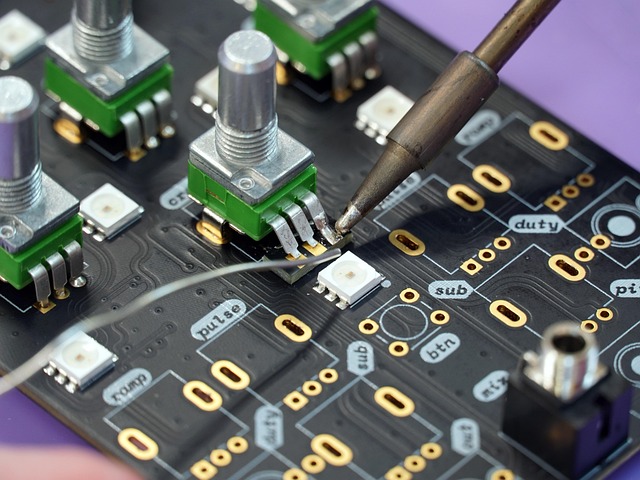

In resistance spot welding, heat is a fundamental element that facilitates the fusion of metal. When an electrical current passes through the weld area, it generates intense heat, rapidly raising the temperature of the metals being joined. This sudden and localized heating is crucial for melting the metal’s surface, allowing it to fuse together under applied pressure. The role of heat in this process cannot be overstated; it’s a game-changer that enables strong, permanent bonds.

Imagine the scenario of car collision repair or body shop services where precision is key. Heat ensures that the welds are consistent and robust, crucial for restoring car bodies to their original integrity. In the world of resistance spot welding, understanding heat’s role is essential for achieving high-quality results in various applications, from automotive manufacturing to complex metal fabrication projects.

The Impact of Pressure on Welding Quality and Strength

In resistance spot welding, pressure plays a pivotal role in achieving high-quality and robust welds. The force applied during the process significantly influences the interaction between the metal surfaces, affecting both the structural integrity and aesthetic appeal of the final join. Optimal pressure ensures that the heat generated by the resistance spot weld effectively melts and fuses the metal, creating a strong bond.

In the context of car collision repair or vehicle repair in general, understanding the impact of pressure is paramount. Proper application of pressure during spot welding can prevent weak spots from forming, ensuring structural stability in vehicles undergoing body work, such as repairing car scratches or dents. This precision is especially critical when dealing with varying metal thicknesses and compositions, which are common in modern automotive manufacturing processes.

Optimizing Heat and Pressure for Efficient Spot Welding

In resistance spot welding, the key to efficiency lies in precise control and optimization of heat and pressure. For optimal results, these factors must be tailored to the specific material being welded. Excessive heat can lead to material distortion or excess melting, while insufficient heat may result in weak welds. Similarly, too much pressure can cause excessive deformation, whereas too little pressure might not fully fuse the metals together.

Welders and auto collision centers often employ advanced techniques and equipment to fine-tune these parameters. By carefully adjusting heat input and pressure application during the welding process, auto glass replacement and frame straightening operations can be efficiently carried out while ensuring structural integrity and quality in repaired vehicles. This meticulous balancing act is crucial for achieving strong, lasting welds that meet industry standards.

Resistance spot welding is a precise process that leverages heat and pressure to create strong, durable bonds. By understanding how heat initiates fusion and pressure enhances it, manufacturers can optimize their welding parameters for improved efficiency and quality. This article has explored the crucial roles of both elements, offering insights into achieving optimal resistance spot welding outcomes.