Resistance Spot Welding (RSW) is a precise manufacturing method using electric current to fuse metal parts, crucial for various industries, especially automotive. Its strength and durability make it essential for structural components, paintless dent repair, tire services, and insurance-backed metalwork repairs. Insurance companies promote RSW to mitigate risks, reduce claims costs, and enhance safety standards by mandating its use in auto body work and collision repair, fostering trust and streamlining the claims process.

In today’s manufacturing landscape, resistance spot welding (RSW) stands out as a critical process ensuring product quality and integrity. This precise technique, involving focused electrical energy to fuse metals, is increasingly becoming a pivotal factor in insurance assessments for industrial risks. As insurers strive to mitigate potential hazards, demanding RSW for coverage offers significant benefits. This article explores the strategic move by insurers to incorporate RSW into their risk management strategies, delving into its advantages and considerations for both policyholders and underwriters.

- Understanding Resistance Spot Welding: A Key Process in Manufacturing

- The Role of Insurance in Industrial Risks and Its Relationship with RSW

- Benefits and Considerations for Insurers When Demanding Resistance Spot Welding for Coverage

Understanding Resistance Spot Welding: A Key Process in Manufacturing

Resistance spot welding is a highly precise and specialized manufacturing process that involves joining two or more metal components together using heat generated by resistance. This method has become an indispensable technique across various industries due to its ability to create strong, durable bonds. By applying electric current through a consumable electrode, the process melts the metal at the joint, resulting in a solid weld. This technology is widely used in automotive manufacturing for fender repair and other structural components, ensuring superior strength and integrity.

Furthermore, resistance spot welding plays a significant role in sectors that require meticulous precision, such as paintless dent repair, where technicians use this technique to fix car bodies without damaging the surrounding paintwork. Its versatility extends to tire services, where it can be employed for various metal fabrication tasks. This advanced welding method guarantees consistent quality and reliability, making it an indispensable tool in modern manufacturing, particularly for insurance companies looking to cover intricate metalwork repairs.

The Role of Insurance in Industrial Risks and Its Relationship with RSW

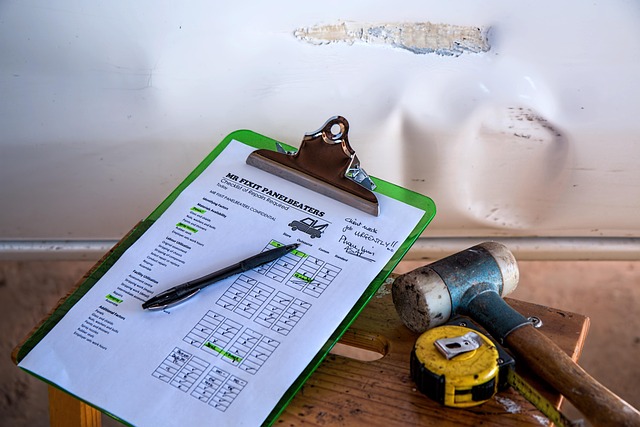

Insurance plays a pivotal role in managing industrial risks across various sectors. In the automotive industry, for instance, insurance providers offer coverage tailored to specific risks associated with vehicle manufacturing and repair. When it comes to ensuring structural integrity and quality control, resistance spot welding (RSW) has emerged as a critical process. Insurance companies have recognized the importance of RSW in preventing potential hazards and minimizing claims related to frame straightening, car paint repair, and auto glass repair.

By mandating or encouraging the use of RSW, insurance providers help maintain safety standards and reduce the likelihood of costly damages. This approach aligns with their broader goal of risk mitigation, ensuring that vehicles on the road meet rigorous safety criteria. Consequently, adopting RSW can lead to more secure operations, fewer incidents, and lower insurance premiums for automotive businesses.

Benefits and Considerations for Insurers When Demanding Resistance Spot Welding for Coverage

Insurers demanding resistance spot welding (RSW) for coverage offer several benefits and considerations for policyholders and the industry as a whole. RSW, a precise and controlled welding technique, enhances structural integrity by creating strong, durable bonds in auto body work and collision repair processes. This advanced method is particularly valuable when assessing and repairing complex vehicle components, ensuring that body shop services meet the highest standards of safety and quality.

For insurers, mandating RSW aligns with their risk management strategies. It provides a more accurate assessment of repair costs and potential structural weaknesses, leading to fairer claims settlements. By prioritizing this specialized technique, insurers can also reduce fraudulent activities in collision repair, as RSW’s precision makes it harder to conceal substandard work. This approach fosters trust between insurers, policyholders, and body shops, ultimately streamlining the claims process and promoting better outcomes in auto body work.

Insurers increasingly demand resistance spot welding (RSW) as a condition for coverage in industrial settings. This trend reflects the recognition of RSW’s critical role in enhancing manufacturing process quality and safety. By mandating RSW, insurers not only mitigate risks but also ensure compliance with industry standards. The benefits extend to both insurers and manufacturers, as RSW improves structural integrity, reduces failure rates, and ultimately contributes to more secure products. This shift underscores the evolving landscape of industrial insurance, where proactive risk management through advanced welding techniques is becoming a standard practice.