Resistance spot welding (RSW) is a cutting-edge process fusing metal components with precision and speed, especially in automotive repair. Using high-energy pulses, RSW creates strong permanent bonds between materials like steel and aluminum while minimizing heat input. High-quality equipment, specialized guns, and compatible electrodes optimize performance, ensuring professional-grade results for car dent and bumper repairs. Advanced techniques including variable resistance machines, automated systems, and CAD software enhance precision and quality, crucial for restoring vehicles to pre-accident condition with minimal distortion or damage.

“Unleash the power of precision with The Complete Guide to Resistance Spot Welding Techniques. Dive into this comprehensive exploration of a pivotal manufacturing process, essential for achieving unparalleled strength in metal fabrication. From mastering the basics to selecting the ideal equipment and materials, we navigate you through every step. Discover advanced techniques ensuring optimal results, transforming your welding capabilities. Whether seasoned or new to resistance spot welding, this guide promises insights tailored to elevate your skills.”

- Understanding Resistance Spot Welding Basics

- Choosing the Right Equipment and Materials

- Advanced Techniques for Optimal Results

Understanding Resistance Spot Welding Basics

Resistance spot welding is a specialized technique used to fuse metal components together with precision and speed. It’s a process that has revolutionized many industries, particularly in automotive repair and vehicle dent repair, offering a more efficient alternative to traditional welding methods. This advanced technique involves the application of a high-energy electrical pulse through a small contact point on the joining surfaces of two or more pieces of metal. The intense heat generated by this pulse fuses the metals together, creating a strong, permanent bond.

This method is widely employed in various sectors for its ability to create consistent and quality welds with minimal heat input. In automotive repair, such as Mercedes-Benz repair, resistance spot welding ensures precise and reliable connections, enhancing structural integrity and vehicle durability. The versatility of this technique allows for the joining of materials like steel, aluminum, and other alloys, making it a go-to solution in modern manufacturing and auto body shops.

Choosing the Right Equipment and Materials

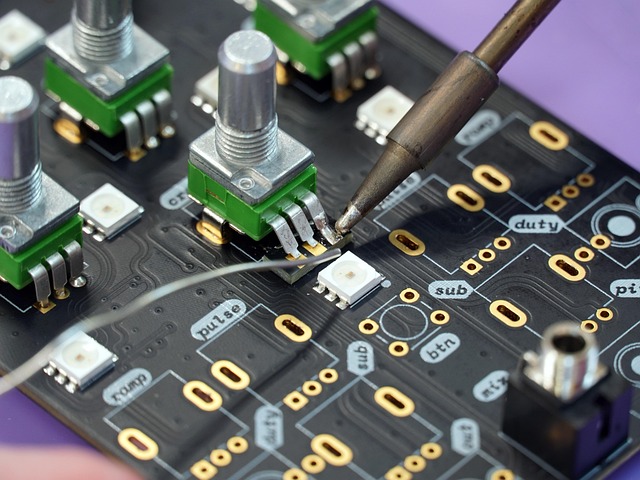

When delving into resistance spot welding, selecting the appropriate equipment and materials is paramount for achieving precision and quality results. The right tools can significantly impact the efficiency and effectiveness of your welds. For instance, high-quality spot welders with adjustable settings cater to various material thicknesses and types, ensuring versatility in your workshop or on-site repair services.

For accurate bumper repair and car dent repair, consider welding guns equipped with different tip sizes and power levels. These tools enable you to make clean, controlled welds, which are crucial for professional collision repair services. Additionally, investing in a supply of compatible electrodes and consumables ensures that your equipment performs optimally during the welding process, allowing you to focus on precision rather than troubleshooting issues.

Advanced Techniques for Optimal Results

To achieve optimal results in resistance spot welding, advanced techniques can significantly enhance precision and quality. One such technique is the use of variable resistance machines, which allow for precise control over weld current, voltage, and pulse duration. This enables welders to adapt to different materials and thicknesses, ensuring consistent and strong bonds without excessive heat input that could distort or damage components, relevant in applications like car dent repair.

Additionally, advanced techniques incorporate automated positioning systems and computer-aided design (CAD) software for precise alignment and measurement. These tools are especially beneficial in automotive collision repair, where quick and accurate welding is crucial to restore vehicles to their pre-accident condition. By combining these advanced methods, resistance spot welding can produce high-quality, durable bonds suitable for a range of industries, including automotive collision repair and car dent repair processes.

Resistance spot welding is a versatile and precise technique that, when mastered, can significantly enhance manufacturing processes. By understanding the fundamentals, selecting the appropriate equipment and materials, and employing advanced techniques, you can achieve superior weld quality and efficiency. This comprehensive guide serves as your starting point, empowering you to navigate the world of resistance spot welding with confidence and expertise.