Resistance spot welding is a highly effective and precise technique for auto body repairs, especially for collision and hail damage. It minimizes heat impact on adjacent components, ensuring strong bonds crucial for structural integrity and preserving the factory finish. Skilled technicians prepare metal surfaces meticulously and control welding parameters precisely to achieve consistent, robust welds that mimic the original factory appearance.

In the realm of collision repair, maintaining the factory appearance of vehicles is paramount to customer satisfaction. Resistance spot welding (RSW) stands out as a pivotal technique for achieving this aesthetic integrity. This article delves into the intricacies of RSW in collision repairs, exploring its advantages over traditional joining methods and highlighting techniques to ensure consistent, high-quality results that rival the original factory finish.

- Understanding Resistance Spot Welding in Collision Repairs

- Advantages of Using Spot Welding for Factory Appearance

- Techniques to Ensure Quality and Consistency in Spot Welding

Understanding Resistance Spot Welding in Collision Repairs

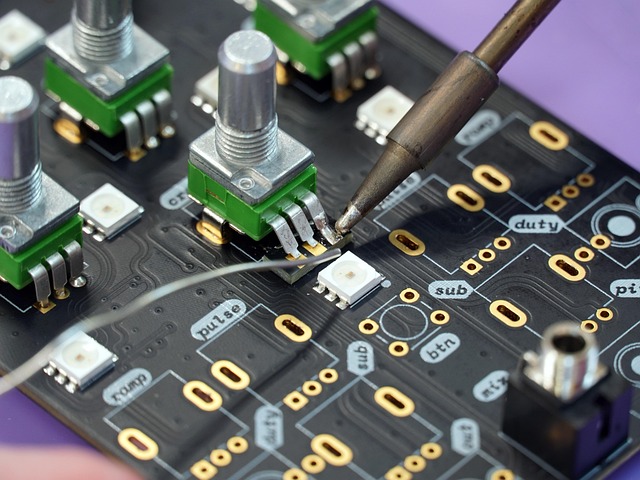

Resistance spot welding is a highly effective technique used extensively in auto body repairs, particularly for collision repairs and hail damage repair. It involves applying heat through an electrical resistance current to melt and fuse two metal pieces together. This precise method ensures strong bonds, making it ideal for structural integrity in car paint repair processes. Unlike other welding techniques, spot welding directly targets specific joints or areas needing reinforcement, minimizing heat impact on adjacent components.

This technology is crucial for maintaining the factory appearance of vehicles during collision repairs. By allowing technicians to make accurate, controlled welds, resistance spot welding helps preserve the original shape and finish, reducing the need for extensive re-body work. Its versatility and efficiency in joining various metals used in modern automobiles make it a cornerstone of professional auto body repairs.

Advantages of Using Spot Welding for Factory Appearance

Spot welding is a highly precise method that plays a pivotal role in maintaining the factory appearance of vehicles during collision repairs. This technique offers several advantages over traditional joining methods, making it an indispensable tool for car bodywork services and auto body shops. By using resistance spot welding, professionals can ensure minimal distortion and consistent results when joining metal panels.

One of its key benefits is the ability to create strong, durable bonds while preserving the original factory finish. This is particularly crucial for car repair services aiming to restore vehicles to their pre-accident condition. Spot welding’s non-invasive nature means less interference with the surrounding surface, ensuring that any repainting or finishing work required after the welds are completed will be as seamless as possible, maintaining the vehicle’s overall aesthetic appeal and market value.

Techniques to Ensure Quality and Consistency in Spot Welding

Achieving quality and consistency in resistance spot welding is paramount for maintaining a factory appearance during collision repairs. Skilled technicians employ several techniques to ensure precision and reliability. The first step involves preparing the metal surfaces, ensuring they are clean, dry, and free from contaminants. This meticulousness sets the stage for strong welds by enhancing surface reactivity.

Next, precise control of welding parameters like current, voltage, and pulse duration is critical. Using specialized equipment, technicians adjust these settings to match the specific alloy and thickness of the metal being welded. Furthermore, maintaining consistent interpass distances and angle adjustments ensures uniform heat distribution, leading to robust welds that replicate the original factory finish in auto maintenance and car restoration processes.

Resistance spot welding is an invaluable technique that not only ensures structural integrity in collision repairs but also maintains the factory appearance of vehicles. By understanding the process, leveraging its advantages, and employing quality control techniques, professionals can achieve precise, consistent, and aesthetically pleasing welds. This, in turn, enhances customer satisfaction and preserves the vehicle’s original aesthetic, making resistance spot welding a true game-changer in the automotive repair industry.