Resistance spot welding is a precise automotive repair technique favored by OEMs for joining metal parts with strong, permanent bonds. It minimizes heat impact, ensures structural integrity, and enhances vehicle longevity, making it ideal for body, fender, and dent repairs. Despite limitations with certain metals and complex joints, its advantages drive its integration into modern repair practices.

Resistance spot welding is a precise and powerful technique that plays a pivotal role in original equipment manufacturer (OEM) repair procedures. This advanced process joins metals by applying heat generated through electrical resistance, making it ideal for complex automotive repairs and precision manufacturing. By understanding the fundamentals of resistance spot welding, we can appreciate its advantages—such as speed, strength, and cost-effectiveness—in OEM settings, while also acknowledging its limitations.

- Understanding Resistance Spot Welding Basics

- Role in Original Equipment Manufacturer (OEM) Repairs

- Advantages and Limitations for OEM Repair Procedures

Understanding Resistance Spot Welding Basics

Resistance spot welding is a specialized technique used in automotive manufacturing and repair, particularly for Original Equipment Manufacturer (OEM) procedures. It involves applying precise electrical resistance to specific points on metal components, causing them to melt and fuse together. This process creates strong, permanent bonds, making it ideal for joining various car parts during both manufacturing and repair processes. For instance, in car restoration or dent removal projects, resistance spot welding can be used to reassemble panels, ensuring a secure and seamless finish.

The method is characterized by its speed, efficiency, and precision. It allows for localized heating, minimizing heat impact on surrounding areas, which is crucial when dealing with delicate or complex car damage repair scenarios. By controlling the amount of current and time, welders can achieve consistent and high-quality bonds, making it a preferred choice in the automotive industry for maintaining structural integrity during repairs and ensuring the longevity of vehicles.

Role in Original Equipment Manufacturer (OEM) Repairs

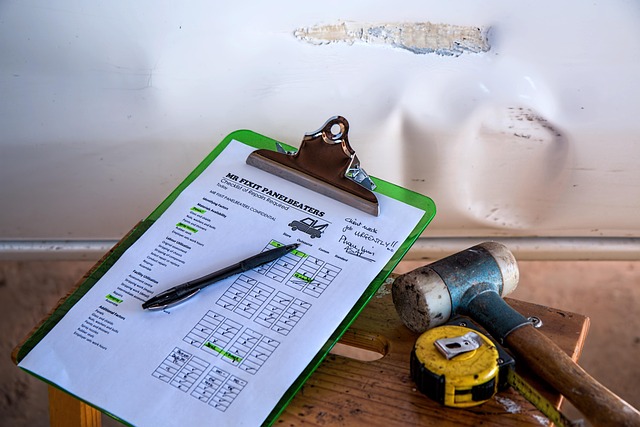

In the realm of Original Equipment Manufacturer (OEM) repairs, resistance spot welding plays a pivotal role in ensuring structural integrity and precision. This versatile technique is particularly valuable for auto body repair, fender repair, and dent repair processes. By applying controlled heat through precise electrical currents, spot welding creates strong, permanent bonds between metal panels, facilitating the restoration of vehicles to their original specifications.

The effectiveness of resistance spot welding lies in its ability to minimize material distortion and reduce the need for excessive filler materials. This not only streamlines the repair process but also enhances the overall quality and longevity of the vehicle’s exterior. As a result, it has become an indispensable method for achieving OEM-quality repairs, catering to both aesthetic and structural demands.

Advantages and Limitations for OEM Repair Procedures

In the realm of OEM repair procedures, resistance spot welding offers several advantages that make it a preferred method for many automotive body work shops and collision centers. This precise technique allows for strong, durable bonds between metal components, ensuring structural integrity in vehicle repairs. Its ability to create consistent welds with minimal heat input helps preserve the original material properties and overall quality of the vehicle’s parts.

However, resistance spot welding also has limitations that must be considered when implementing OEM repair procedures. The process requires specialized equipment and skilled technicians, which can increase operational costs for collision centers and tire services. Furthermore, it may not be suitable for all types of metals or complex geometric joints, necessitating additional preparation steps or alternative joining methods. Nonetheless, understanding these advantages and limitations is crucial for effectively integrating resistance spot welding into modern automotive repair practices.

Resistance spot welding is a versatile and powerful technique that plays a significant role in Original Equipment Manufacturer (OEM) repair procedures. Its advantages, such as high strength, precision, and material conservation, make it an ideal choice for restoring components to like-new condition. However, like any process, it has limitations, including cost and specialized equipment requirements. By understanding the basics of resistance spot welding, its benefits in OEM repairs, and its drawbacks, professionals can make informed decisions to ensure effective and efficient repair outcomes.