Resistance spot welding is a game-changer in auto body repairs, offering precision and strength with minimal material removal, heat input, and waste. This method reduces repair times, saves energy, and enhances joint integrity, making it crucial for modern workshops. However, effective implementation requires training staff to use specialized equipment safely and efficiently.

Resistance spot welding is a game-changer for repair shops, offering precise and efficient joining of metals. This powerful technique has revolutionized automotive repairs, ensuring stronger and more reliable connections. In this article, we explore the impact of resistance spot welding on your shop, from understanding its techniques to uncovering its advantages in speed and efficiency. We’ll also navigate challenges and provide best practices for successful implementation, helping you harness the full potential of this modern welding method.

- Understanding Resistance Spot Welding Techniques

- Advantages and Efficiency in Repair Shops

- Challenges and Best Practices for Implementation

Understanding Resistance Spot Welding Techniques

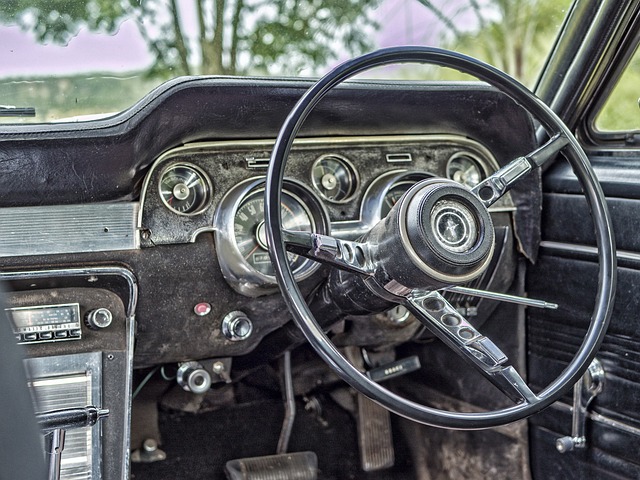

Resistance spot welding is a precision technique that has transformed auto body repairs. Unlike traditional welding methods, it focuses energy directly onto a specific point to melt and fuse metals together. This process involves applying pressure while passing an electric current through the materials being joined, creating a strong, precise bond. It’s particularly valuable for car collision repair as it allows for intricate and subtle fixes without disturbing surrounding metalwork.

This method is highly effective for both structural repairs and assembling components in auto body shops. The ability to weld with precision means less material removal and minimal heat input, preserving the integrity of surrounding parts. For those seeking reliable and expert auto repair near me, understanding that resistance spot welding is a key skill sets apart shops that prioritize quality and efficiency in their car collision repair services.

Advantages and Efficiency in Repair Shops

Resistance spot welding offers significant advantages for repair shops, revolutionizing the way they handle autibody repairs and vehicle bodywork. This precise and efficient technique allows for faster cycle times, reducing the overall duration of vehicle repair processes. With its ability to create strong, durable bonds, resistance spot welding ensures superior joint strength, which is crucial in maintaining the integrity of vehicle structures.

The efficiency gains are substantial, as this method minimizes material waste and energy consumption compared to traditional welding techniques. This not only translates to cost savings for repair shops but also contributes to a more sustainable approach to vehicle repair. The consistent quality and reliability of resistance spot welding make it an indispensable tool in modern workshops, catering to the diverse needs of vehicle bodywork repairs.

Challenges and Best Practices for Implementation

Implementing resistance spot welding into your car repair shop brings both challenges and significant advantages for automotive body work. One of the primary hurdles is training staff to operate this specialized equipment effectively. Proper technique is crucial to prevent damage to components, especially in intricate auto body services where precision is key.

Best practices involve investing in high-quality welding machines and maintaining them regularly. Establishing standard operating procedures ensures consistency and reduces the risk of errors. Additionally, fostering a culture of safety by providing adequate personal protective equipment (PPE) and implementing strict protocol for handling hot materials is essential. Regular staff training sessions on resistance spot welding techniques will not only enhance productivity but also improve the overall quality of auto body repairs in your shop.

Resistance spot welding offers repair shops a powerful tool for efficient, high-quality repairs. By understanding its techniques, leveraging its advantages, and addressing implementation challenges through best practices, shops can enhance productivity, reduce costs, and deliver superior results. Resistance spot welding is not just a process; it’s a strategy to stay competitive in today’s automotive landscape.